- + 32 60 51 25 85

- contact@graux.be

- Monday to Thursday : 07:30-12:00am and 00:30-04:30pm • Friday : 7:30-12:30am

Menu

quality

Thanks to its unique experience on the market, GRAUX has a structure that meets the expectations of industrial clients: a flexible, safe and controlled organization to ensure quality, respect of deadlines and safety in each project.

How do we get it?

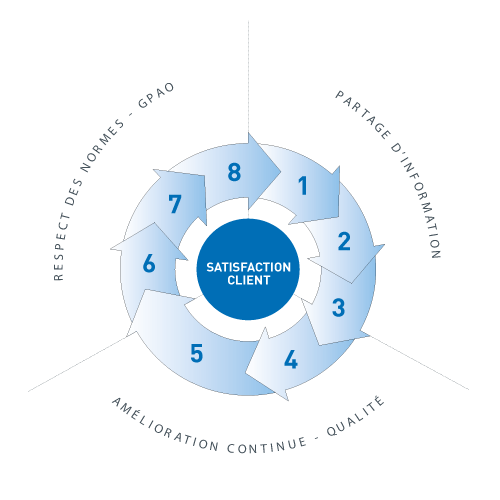

Driven by a fully integrated ERP, all flow management processes are standardized and continuously evaluated to guarantee a quality product and service.

From the offer to the guarantee.

Here are the main steps:

Men close to their customers with a constant concern for quality.

A permanent and privileged customer-supplier relationship for a high level of manufacturing.

GRAUX is a major supplier for our institute (nuclear). The competitiveness of the calls to tender, the quality of the execution of the services and the quality files as well as the respect of the deadlines are for us undeniable assets. Sympathy and ease of relationship are a plus.

I appreciate working with GRAUX, both for the quality of their workmanship, their flexibility, their competitiveness and their responsiveness. We have been working together for many years, and the exchanges are all the more pleasant.

Dynamic team responding with professionalism and able to advise us during our studies. Over the course of our projects, we are always delighted with the work done, without surprises and respecting our various design constraints.

For more than 20 years now, we have enjoyed a solid and reliable partnership with the company GRAUX! Their highly qualified teams are always ready to take on new technical and technological challenges, while remaining at our disposal for quality improvement. Thanks to their professionalism, their expertise and their family spirit, both of them took us to the top!

contact

We are at your disposal and

we respond quickly to your requests.

From the simplest to the most complex.