- + 32 60 51 25 85

- contact@graux.be

- Monday to Thursday : 07:30-12:00am and 00:30-04:30pm • Friday : 7:30-12:30am

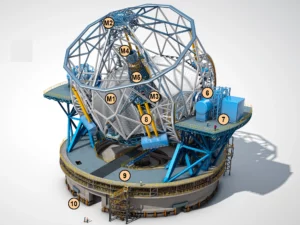

The European Extremely Large Telescope (ELT) is the most ambitious project in the world and is carried by the European Southern Observatory (ESO). This telescope should allow major advances in the field of astronomy, in particular thanks to its primary mirror with a diameter of 39 meters.

When in June 2012, the ESO Board of Directors approved the budget for the construction of the giant telescope, the Dutch Minister of Education, Culture and Science, Maria van der Hoeven declared “An almost unique level of international cooperation is achieved at ESO, and everything is done by those who can do it best, regardless of their country or institution. This spirit of excellence is an example for all Europe.” (ed. A rare level of international cooperation is achieved at ESO. Everything is done by those who are able to produce the best, regardless of their country or institution. This spirit of excellence is an example for all of Europe).

GRAUX is committed to excellence and has leading-edge expertise in the manufacture of industrial equipment using high vacuum technology. For these and other reasons, GRAUX was chosen to manufacture the processing tools and stainless steel conveyors for the mirror segments.

The ELT telescope is composed of several mirrors of impressive size which required extremely thorough studies and a level of production precision not previously achieved.

Among these, the main primary mirror M1 (f/0.93) of the ELT has a diameter of 39 meters and, given its size, uses the technique of the segmented mirror, that is to say that it is formed by the assembly of several “small” mirrors. It consists of 798 hexagonal elements of 1.45 meters in diameter and 40 millimeters thick assembled like those of the Keck telescope in Hawaii. The mass of the primary mirror is 150 tons. The M1 mirror is supported by 30,000 supports that correct in real time the forces due to the bending and deformation movements generated by the wind and the rotation of the mirror.

These mirrors must receive a specific treatment renewed regularly. For this reason and given that the telescope is installed at an altitude of 3,000 meters in the Atacama Desert in northern Chile, ESO is building a processing plant for mirror segments next to the giant telescope.

This specific treatment takes place under vacuum and requires specific tools to handle the mirrors in the vacuum chambers. And as it happens in Chile, the whole plant and all the tools must be able to handle the seismic shocks without breaking glass…

Extreme conditions motivated the establishment of demanding specifications that GRAUX was able to win against high-level competition.