- + 32 60 51 25 85

- contact@graux.be

- Monday to Thursday : 07:30-12:00am and 00:30-04:30pm • Friday : 7:30-12:30am

our history

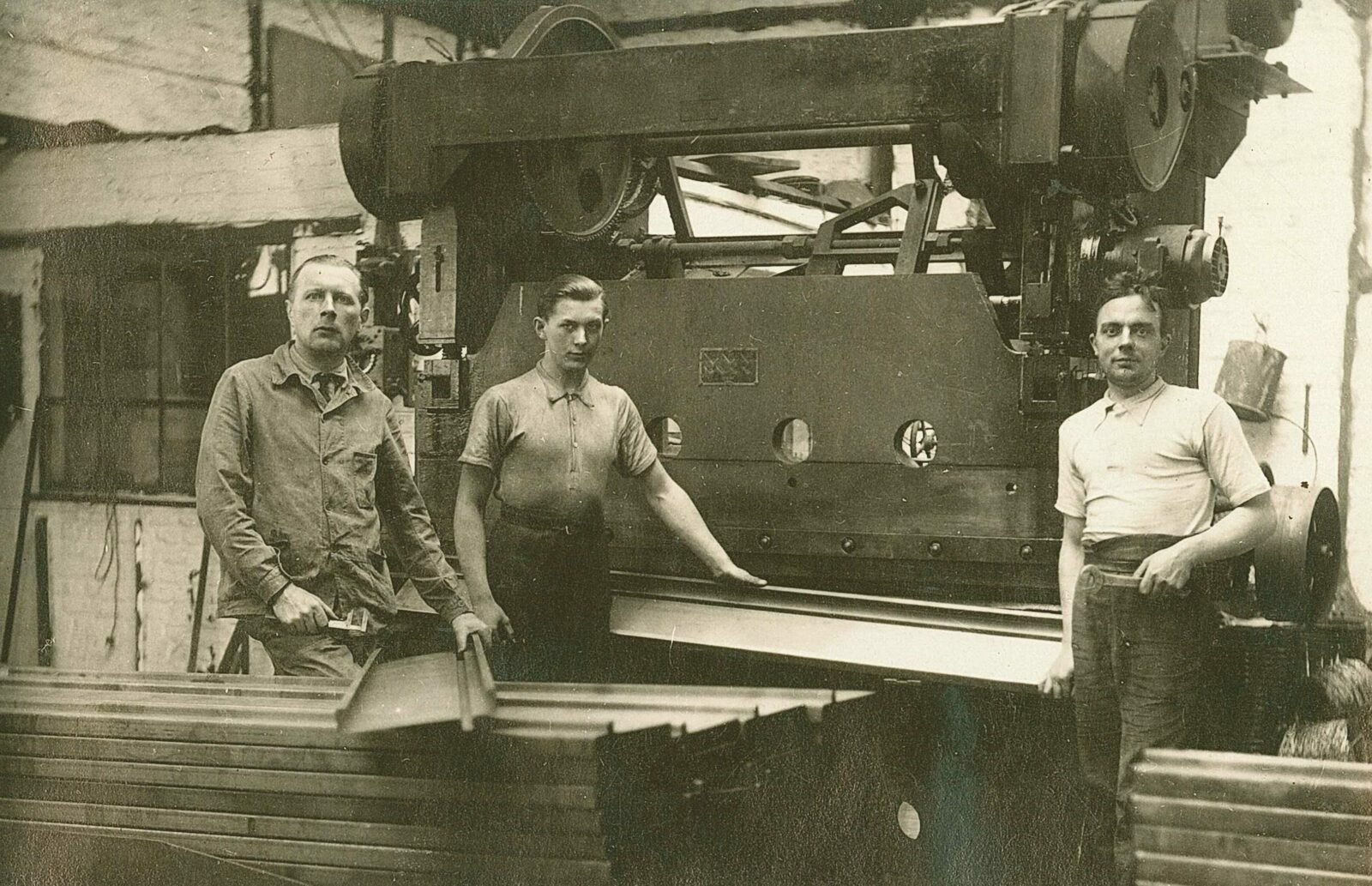

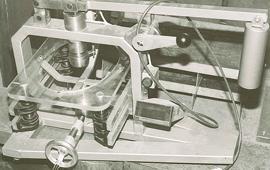

Since its inception, GRAUX has been able to stay ahead of the curve by having the latest technology available for its businesses. For example by having the first press brake in Belgium (picture).

Whether in terms of technical skills, equipment, machinery, management methods, standardization and complexity of the projects entrusted, the family business has always aimed for the best performance. This concern for perfection has led to the evolution of the small workshop from its beginnings to the present structure, solid and concerned with meeting 100% of the increasingly complex needs of its customers.

This strong position has made the company a reference in the field of mechanical welding and special machine construction for industry.

Foundation of the company by Henri GRAUX, engineer, and his wife Louise by the purchase of the company COMEMO (COnstructions MEtalliques de MOmignies) which has the first mechanical press brake in Belgium.

during this time, we hear on the radio…

The turnover is 350.000 FB (± 9.000 EUR) and three workers work with Henri GRAUX. His son, Albert, after attending the Gramme Institute in Liege, joins the family business. He is committed to structuring the production and developing the customer base.

at this time, Annie Cordy sings…

The commercial efforts succeeded and many machine manufacturers entrusted the realization of their fairings and/or chassis to GRAUX. The clients at that time were Imperia, La Mondiale, Hydrobel, Defawes, De Moor, Jaspar, Dutranoit. Seven workers are part of the team.

at this time, Elvis plays…

The collaboration with Sabena begins. The first order is a set of complex covers. Electrical cabinets are also manufactured for the engine manufacturer Moës.

at this time, the n°1 of the Belgian hit-parade is…

Sabena entrusts the realization of handling carts for Boeing 707 engines as well as test groups.

at this time, the n°1 of the Belgian hit-parade is…

At the beginning of the 1970s, the economic situation became darker due to the galloping inflation and many customers disappeared. Nevertheless, new perspectives are opening up in the world of glass with the first order from Glaverbel for mechanical hangers.

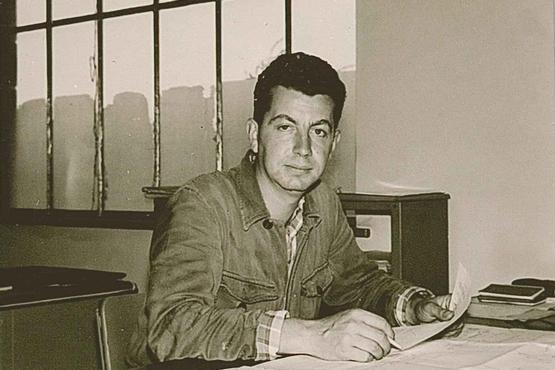

In 1972, Albert GRAUX bought the company from his parents and developed exchanges with the manufacturer of boring machines Pegard who entrusted the company with all its fairings.

1972, it’s Monday in the sun ….

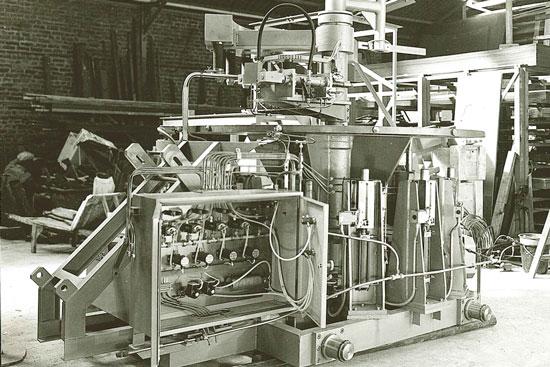

In association with SECMA, the workshop manufactures various machines in steel and stainless steel. To carry out these projects, investments in welding and mechanical equipment will be made.

Arrival of Marc Chanteux, husband of Béatrice GRAUX, daughter of Albert. Creation of a limited company, the “ACM Momignies” in parallel with the activity as a physical person.

1980, it is France Gall who reigns on the hit parade

Relocation to the current site, in the industrial zone, to occupy a first building of 1,000 m² equipped with a 5 T crane. The mechanical capacities increase and the activity is oriented towards heavier mechanical welding while maintaining the sheet metal work. The staff is composed of 17 workers and 3 employees. The partnership with Glaverbel is intensified and complete mechanized sets are taken over.

Beginning of the collaboration with DONNAY. Testing machines and sieve markers are made at GRAUX.

at this time, we are in the middle of the 80s …

Construction of a second building of 1.000 m². The team is now composed of 21 people including an electromechanical engineer who supervises the manufacturing process.

Merger of ACM and Ateliers GRAUX to become a single company: “S.A. Ateliers GRAUX”. Albert GRAUX is the Managing Director and Marc CHANTEUX is the Director.

at this time, we are at the height of the Queen …

Arrival of the first milling machines, large boring machines, a CNC bending machine and the Hartford CNC machining center

Construction of a third, longer building to bring the total surface area to 3,250 m²; it is mainly intended for finishing (paint booths) and assembly of turnkey industrial units. The total staff is 22 people.

On the radio and on TV, it’s the time of the Boys Band …

Graux enlists the help of a mechanical engineer: David Dutront.

at that time, David was dancing on Blue …

Albert GRAUX retires and Marc Chanteux becomes managing director.

The American hit of the moment is ….

Extension of 1.200m² in extension of the 3 buildings and creation of an internal store of 250m². The total area now exceeds 5,000 m². Regular investments in welding stations and numerical machine tools, especially in long milling (6m and 8m). The turnover exceeds 5 million euros.

The entire process is centralized in a CAPM (Computer Aided Production Management). An additional Mechanical Engineer, Alain Sobry, joins the team to manage production and planning.

Julien Chanteux, Marc’s son, joins the management team and represents the 4th generation of GRAUX’s development. A 3D drawing software is installed. It facilitates the preparation of sheet metal parts and imports any type of CAD format.

at this time, it is Bruno Mars who is listened in loop

The 5-axis makes its appearance through a Huron machining center with a 2,900mm table. A MAZAK 4-axis turning/milling center is also installed.

The team now numbers 35 people and project management is becoming more complex. The implementation of a project-based organization is essential. SPOCs (Single Point Of Contact), known as Project Managers, take charge of each project, from its costing to its delivery. The customer gains in reactivity and efficiency.

GRAUX obtains ISO 9001 certification, thanks to the participation of all its 35 employees.

2013 is the year of Stromae with “tous les mêmes”

New wave of investment (> 1,000,000 €) in numerical control machines: LVD bending machine, VTC machining center with very high feed rate, high capacity turning center (Ø 920 by 3m long).

The workshop’s electricity consumption is an important issue, both in terms of management and environmental responsibility. A sustainable solution was developed in partnership with the Issol company to place 343 photovoltaic panels on the roof. This production of approximately 100 Mwh will meet a significant portion of our needs and makes GRAUX the largest producer of photovoltaic electricity in the Chimay region.

This is the first step towards ensuring that all our consumption is green and responsible.

Graux is certified ISO 3834-2: Quality certification of welding processes to guarantee the high level of execution of the welds. In line with the arrival of a new engineer, international welding specialist, Nicolas Bénézit.

GRAUX is equipped with a new “large size” milling machine, a Soraluce with a head indexable to a thousandth of a degree.

2017 is “Shape of you”, by Ed Sheeran

At the end of August 2018, Marc is taking a well-deserved retirement after actively growing the business for 40 years. Julien, after 8 years of collaboration with his father, takes over the reins of the company alone. He is now the 4th generation at the head of Graux, after Henri, Albert and Marc.

A Soraluce Floor Type that can mill 8000mm long, 3100mm high and 1600mm wide with an accuracy of 0.02mm/m has considerably increased the capacity of our machine park

An additional building is built and brings the total surface to a little less than 7000 m².

In 2019, it’s Angèle who is enthroned on the Belgian ultratop!

Our assemblies requiring a clean environment can be carried out in a specific dust-proof area of 16 x 10 m with a 5T bridge.

2020 is the year of The Weeknd!

For manufacturing requiring special protection of materials such as aluminum or stainless steel for nuclear or food applications, we work in a dedicated room of 160 m², separated from the rest of the boiler room.

2020 is the year of The Weeknd!