- + 32 60 51 25 85

- contact@graux.be

- Monday to Thursday : 07:30-12:00am and 00:30-04:30pm • Friday : 7:30-12:30am

GRAUX brings together all the skills and competencies of the value chain for the manufacture and assembly of special industrial machines.

GRAUX brings together all the skills and competencies of the value chain for the manufacture and assembly of special industrial machines.

Among these activities, we are internationally recognized by leading clients for our expertise in :

Discover these 4 areas of expertise in detail below.

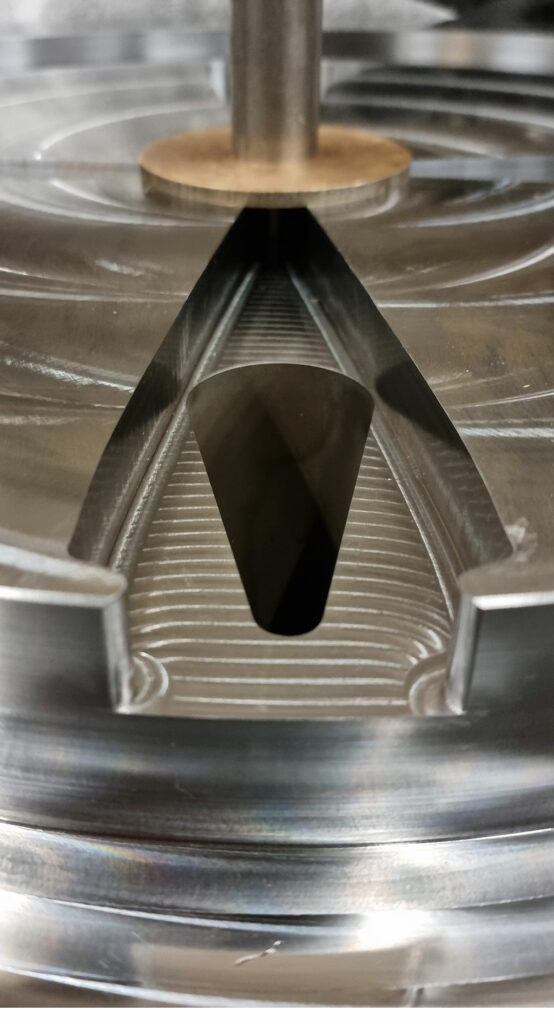

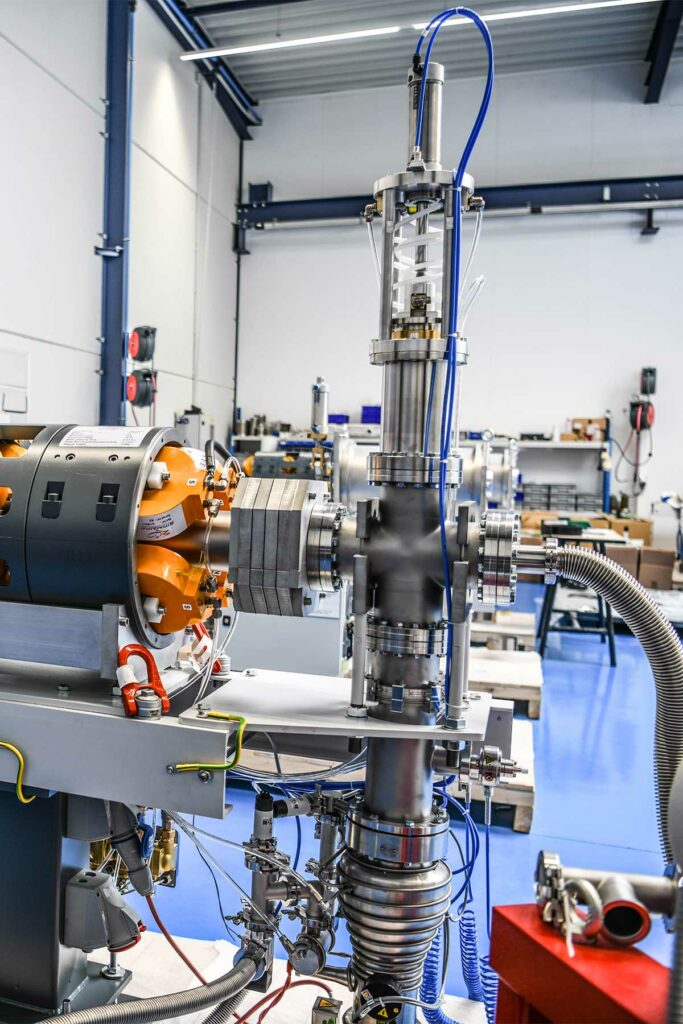

With more than 10 years of experience in the manufacture of vacuum assemblies, we have gained international recognition and expertise in the manufacture, assembly and quality control of vacuum assemblies and machines. Including those related to ion implantation technology.

Thanks to our partnership with the Walibeam technological competence center, we have developed extensive experience in mastering manufacturing processes to produce assemblies subjected to primary vacuum, secondary vacuum and Ultra High Vacuum (UHV).

With our partners, we have been able to achieve a WORLDWIDE INNOVATION allowing to perform ion implantation on continuously moving gritted strips. See this project.

Our engineers and operators have been specially trained in vacuum techniques and are certified for technical control and leak detection.

This know-how has enabled us to manufacture vacuum assemblies for the glass, space, watchmaking and nuclear research sectors.

our business assets

Certified to ISO 3834 level 2 (the highest level of the standard), GRAUX guarantees the highest quality welding.

In addition to their practical experience, each welder is certified according to the ISO 9606-1:2012 standard on numerous welding procedures. Whatever the type, position, metal, thickness, filler metal, you will always find a qualified welder at GRAUX.

On request, our international welding specialist (IWS) will draw up a welding booklet specific to your project, including welding plans, complete traceability of materials, traceability of filler metals, welding procedure qualifications (QMOS / WPQ), welding procedure demonstrations (DMOS / WPS), non-destructive testing (PT; MT; UT) or destructive testing.

The Project Managers are also welding coordinators in order to carry out in-process and end-of-production controls on all your welds.

our business assets

GRAUX meets specific production requirements and specifications in the vacuum, nuclear and medical sectors. Production equipment and expertise that perfectly complements our production line and capabilities. Rare assets on the market.

A new room dedicated to assemblies requiring a clean environment and special precautions completes our production infrastructure.

It meets the quality requirements imposed during the assembly of machines and assemblies dedicated to the vacuum, nuclear or medical sectors.

In addition, for parts subject to vacuum, we can now perform all leak tests at our production site. The customer is thus assured of the minimum tightness achievable on site. This vacuum level can be further improved after a longer degassing.

Our engineers and operators have been specially trained in vacuum techniques and are certified for technical control and leak detection.

our business assets

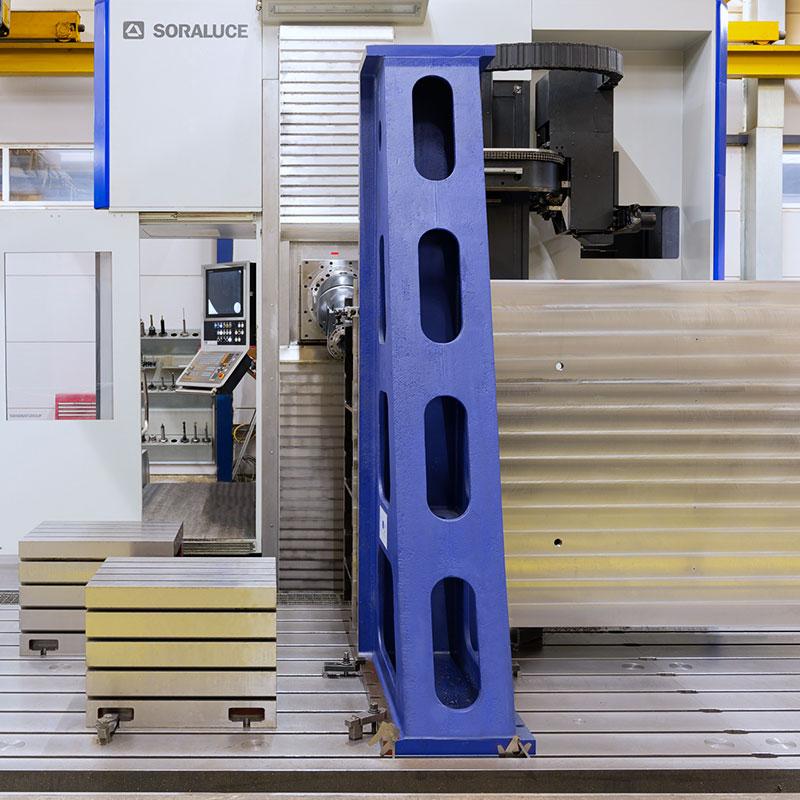

GRAUX’s machine park is unique in the region.

GRAUX is equipped in-house to manufacture all components of a machine, from the small roller axle in turning to the milling of a welded frame of 8000mm long, 3100mm high and 1600mm deep.

The accuracy depends on the structure of the part but can be as low as 0.02mm/m.

In large dimensions, 4 milling machines from 6500 to 8000 mm, 1 boring machine and 1 horizontal lathe of Ø930mm are available to realize your non-standard parts.

GRAUX se distingue de ses concurrents en tant qu’atelier de mécanique, par sa taille moyenne et la disponibilité de ses dirigeants et des responsables de projet.

Men close to their customers with a constant concern for quality.

A permanent and privileged customer-supplier relationship for a high level of manufacturing.

GRAUX is a major supplier for our institute (nuclear). The competitiveness of the calls to tender, the quality of the execution of the services and the quality files as well as the respect of the deadlines are for us undeniable assets. Sympathy and ease of relationship are a plus.

I appreciate working with GRAUX, both for the quality of their workmanship, their flexibility, their competitiveness and their responsiveness. We have been working together for many years, and the exchanges are all the more pleasant.

Dynamic team responding with professionalism and able to advise us during our studies. Over the course of our projects, we are always delighted with the work done, without surprises and respecting our various design constraints.

For more than 20 years now, we have enjoyed a solid and reliable partnership with the company GRAUX! Their highly qualified teams are always ready to take on new technical and technological challenges, while remaining at our disposal for quality improvement. Thanks to their professionalism, their expertise and their family spirit, both of them took us to the top!

GRAUX distinguishes itself from its competitors as a mechanical workshop by its medium size and the availability of its managers and project leaders.

As far as we are concerned, GRAUX has several important assets: high flexibility, great adaptability and a very high level of technicality in the work. In addition, GRAUX is very reasonably priced, without compromising on technical and quality aspects.

GRAUX se distingue de ses concurrents en tant qu’atelier de mécanique, par sa taille moyenne et la disponibilité de ses dirigeants et des responsables de projet.

Men close to their customers with a constant concern for quality.

A permanent and privileged customer-supplier relationship for a high level of manufacturing.

GRAUX is a major supplier for our institute (nuclear). The competitiveness of the calls to tender, the quality of the execution of the services and the quality files as well as the respect of the deadlines are for us undeniable assets. Sympathy and ease of relationship are a plus.

I appreciate working with GRAUX, both for the quality of their workmanship, their flexibility, their competitiveness and their responsiveness. We have been working together for many years, and the exchanges are all the more pleasant.

Dynamic team responding with professionalism and able to advise us during our studies. Over the course of our projects, we are always delighted with the work done, without surprises and respecting our various design constraints.

For more than 20 years now, we have enjoyed a solid and reliable partnership with the company GRAUX! Their highly qualified teams are always ready to take on new technical and technological challenges, while remaining at our disposal for quality improvement. Thanks to their professionalism, their expertise and their family spirit, both of them took us to the top!

GRAUX distinguishes itself from its competitors as a mechanical workshop by its medium size and the availability of its managers and project leaders.

As far as we are concerned, GRAUX has several important assets: high flexibility, great adaptability and a very high level of technicality in the work. In addition, GRAUX is very reasonably priced, without compromising on technical and quality aspects.

GRAUX se distingue de ses concurrents en tant qu’atelier de mécanique, par sa taille moyenne et la disponibilité de ses dirigeants et des responsables de projet.

contact

We are at your disposal and

we respond quickly to your requests.

From the simplest to the most complex.